Cable harnesses

More than 60 percent of all our deliveries are cable harnesses. Fully labeled and commissioned for easy assembling also in returnable packaging. Including individual labeling which can vary from machine to machine.

Cable harnesses according to assembly stage

We put together cable harnesses according to the needs of the customer. We commission individual cable packets depending on each step of installation on the machine. We deliver trolleys directly to the machines.

According to circuit diagram, according to applications, your engineering, our details

We are specialists when it comes to machine cabling. We assist you with all details. We sort out protrusions, the selection of components and we recommend the appropriate cable quality depending on which application.

According to circuit diagram, according to application, your engineering, our details

According to circuit diagram, according to application, your engineering, our details

We are the specialists for machine cabling. We support you with the details. We clarify overhangs, the component selection and we suggest you the appropriate cable quality depending on the application.

Cable drag chains – ready to install

We provide you with assembled, ready-to-install energy guiding chains in many variations and designs. We have many years of  experience in design and professional assembly. We equip chains with power and signal cables, hydraulic, pneumatic, coolant and lubricant hoses. The complete chain system is completely strain-relieved and assembled with mudguards.

experience in design and professional assembly. We equip chains with power and signal cables, hydraulic, pneumatic, coolant and lubricant hoses. The complete chain system is completely strain-relieved and assembled with mudguards.

Upon request, we make tests according to the customer requirement. In order to meet your warranty claims, we offer an on-site assembly service for chain systems.

The topic “Preventive maintenance” is part of our daily business. On request visit as the operating sites of the machines worldwide and check the chains. After producing a detailed report on the current state of the chain system, we can carry out on-site maintenance to the end customer.

Construction projects: Creation of specifications, design and construction, drawing and documentation, prototype production and assembly, delivery program

We are happy to support our customers with complete cable harness projects. We look at what needs to be done together with our customers to set the specifications to specify the details of the desired result in advance. We construct the cable set, take over the component selection and create the documentation including circuit diagrams, drawings, specifications and installation plan. We manufacture the prototypes and assemble them. Before the start of serial production, we bring in the latest changes.

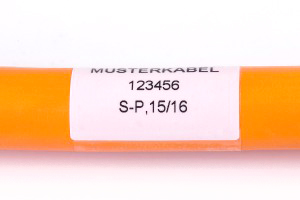

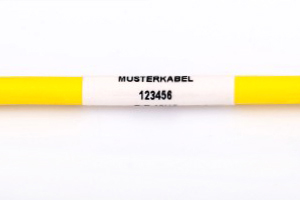

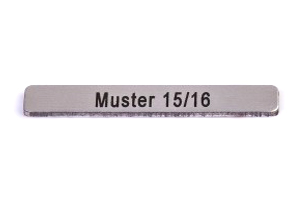

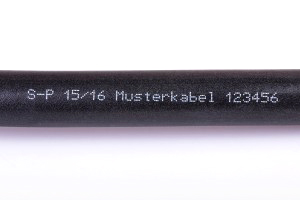

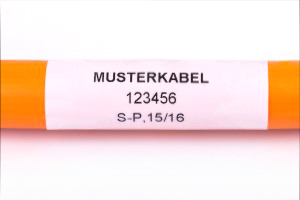

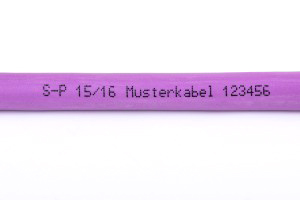

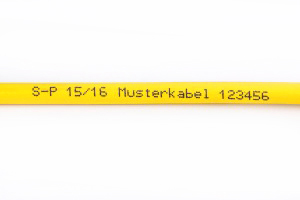

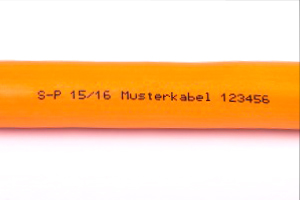

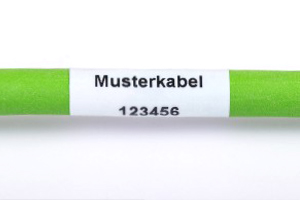

Individual project signs

Thanks to our IT solution, it is possible to quickly and easily define individual signage for existing machine cabling. The respective label is traceable in our IT for all time. Even short-term changes can be made until just before the start of production. In addition to our standard labeling options, the customer is of course free to choose other printings or signage.