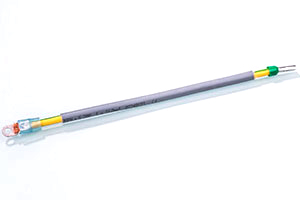

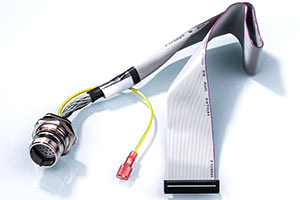

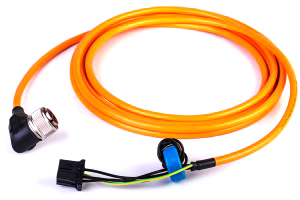

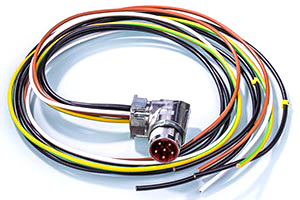

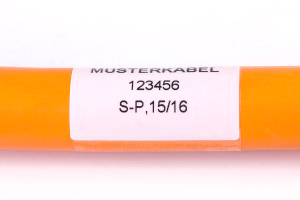

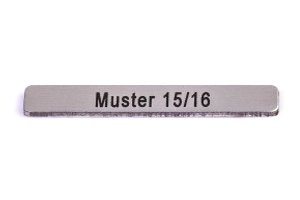

Cable assembly individually

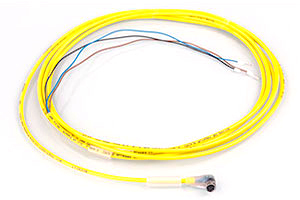

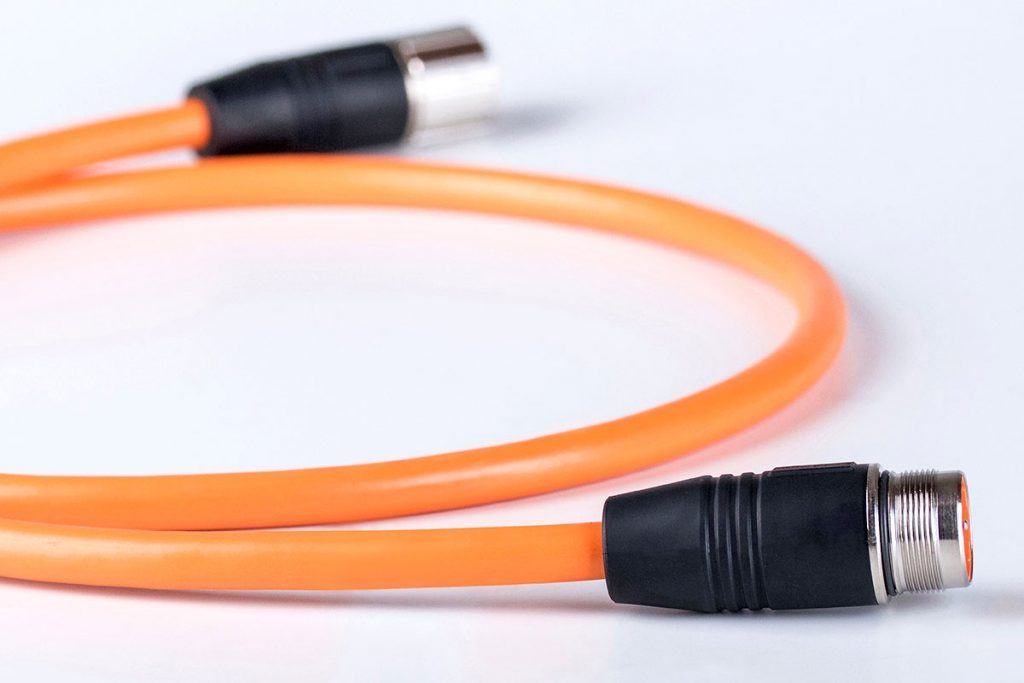

In addition to the servomotor cabling, we manufacture a wide variety of cables. We integrate M12 into marked cable sets, process ribbon cables, assemble the connections to terminals, fit cable bushings and bulkhead plates, configure hose packages or create individual wiring harnesses for our customers. New are the possibilities that result from the hotmelt technology. Every day new types are added. Together with our customers, we work out the appropriate solution. We are your specialist for the right machine cabling. Special applications for special applications belong to our daily business. We are happy to help.

At the location in Weil im Schönbuch we operate one of the most efficient cable manufacturing companies especially for the needs of mechanical and plant engineering. Our strength is the individual delivery of small individual approvals, each suitable for the specific application.

In addition, we have created manufacturing capacity that enables cost-effective production of large to large volumes. Quantities range from 500 to more than 100,000 pieces.